NASH held day two of their annual conference at University of Auckland’s Engineering School. The preceding day NASH members had the opportunity for a guided tour at New Zealand Steel’s Glenbrook site. With the recent announcement from NZ Steel and the Government on the co-investment on the EAF made the site tour all the more interesting.

Guest speakers day 2

Scott Morrison – Fletcher Steel.

Scott’s presentation was on “Green Steel – Future Outlook”. Scott recently attend the European Green Steel Summit in Germany, and provided an overview on what is green steel and had an update on the various projects being undertaken by the European manufacturers.

John Jamieson – Winstone Wallboards

Winstone Wallboards are about to open their new manufacturing and distribution centre in Tauranga, it has been several years from initial design phase to the opening. The new plant integrates state of the art technology that include sustainability initiatives into the design and operation of the building.

Another innovation is that production wastewater will be collected and recycled back into the manufacturing process eliminating. New plasterboard waste can be recycled, this will assist the building industry in limiting the plasterboard waste going into landfill and integrating more recycled building materials and working in a more circular way.

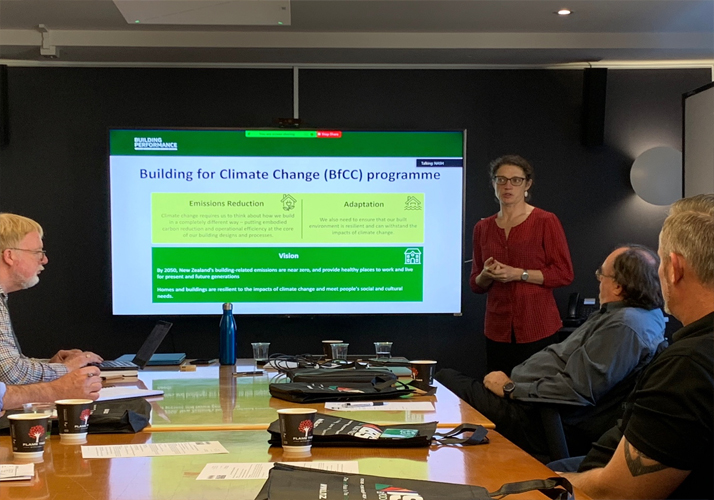

Katie Symons – MBIE – Building for Climate Change, Embodied carbon methodology

MBIE’s Building for Climate Change Programme, BfCC, is responsible for leading the building and construction sector’s response to the climate crisis. The vision for BfCC is that by 2050, New Zealand’s building-related emissions are near zero, and provide healthy places to work and liver for present and future generations. Homes and buildings are resilient to the impacts of climate change and meet people’s social and cultural needs.

For Building and Construction the objectives are to reduce embodied carbon in buildings and reduce operational emissions. The focus area are to:

- Reduce embodied carbon of construction material and buildings

- Accelerate the shift to low-emissions buildings

- Improve building and energy efficiency

- Shift energy use from fossil fuels

- Establish foundations for future emission reduction

For NASH members they need to be aware that in 2024 there is consultation period on Building Code compliance pathways for embodied carbon requirement. From 2025 new building reporting requirements for embodied carbon emissions begin and in 2026-2029 there is a phased lowering of caps for embodied carbon emissions in new buildings. NASH members should familiarise themselves with the new regulatory requirements that are coming in 2025. The Government wants to work collaboratively with the sector so NASH members need to engage.

Jeremy Smith – New Zealand Steel

There has been a lot in the media about the future of steelmaking in New Zealand with the announcement of the co-funded project between NZ Steel and the Government. The electric arc furnace will secure the future of steelmaking at the Glenbrook site and will reduce the carbon footprint by 1% of the country’s annual emissions, with NZ Steel’s emission being reduced by >45%. The EAF will consume 300,000 tonnes of domestic scrap steel and will be powered by an average of 30MWH firmed renewably generated power.

For NASH members this provides a security of supply. The blue surface treatment is due to begin in May and this will differentiate AXXIS® from commodity galvanised steel. The blue treatment will enable easy identification and confirmation that the steel has been manufactured to the relevant NZ Standards. NZ Steel are working with NASH to deliver content and assistance to “normalise steelframing”.

Gordon Barratt – NASH member – Steel-it

Gordon has been a involved with steel framing for many years, having been a valued member of the NASH executive board and also holding the position of chairman. Gordon’s presented the his mid-rise construction case study reminding the members to

- Initial consultation

- Draft costings

- Plans/ Design

- Detail costings – prior to engineering

- Final engineering/ steel frame conversion

- Final costings – what’s included in the detail

- Prelet meeting

- Contract – Check everything/ detailed timetable

- Production

- Storage

- Delivery & tracking

- Site inspections/ issues assistance

- Final certificate

- Final claims/ Rententions